Why Does Film Coating Require Lower Viscosity?

Film coating, sometimes called curtain or fan coating, can sometimes be the preferred approach to conformal coating when high speeds and precise edge or border control are critical. As can be imagined, atomized spray can, in certain instances, be inferior due to the difficulty of completely and accurately controlling where each and every droplet may land.

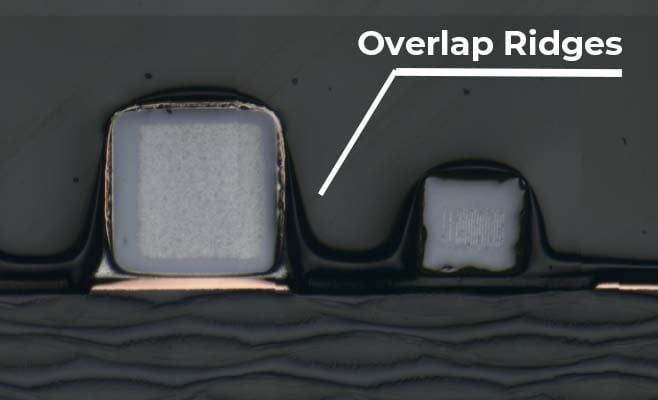

On the other hand, one disadvantage of film coating can be the challenge of getting an even thickness across multiple passes of the coating head. Each pass of the valve head lays down a consistent amount and thickness of the coating, but due to the need to overlap the passes, there will be small areas or ridges that contain nearly double the desired thickness. To alleviate or eliminate this effect, it is desirable that the coating be shallow in thickness or viscosity to allow it to flow quickly and self-level before reaching the curing unit.

The Solution: Humiseal UV80 and UV80LED

HumiSeal has developed a number of low-viscosity, UV-curable conformal coatings that are suitable for film coating and other applications where thinner coatings are appropriate. UV80 and UV80LED are provided at a viscosity of 80CPS to allow for sufficient flow and self-leveling, resulting in a uniform coating thickness and minimizing overlapping ridges when film coating. UV80 requires a whole spectrum UV curing bulb, while UV80LED was designed recently to cure fully with single wavelength LED-type lights. These products provide the superior protection the industry has come to expect from all Humiseal conformal coatings with the high flow characteristics required of film coating.

Learn more: UV80LED LV

Contact our sales!