The global market for ESD packaging materials is growing rapidly. In 2025, it is estimated to be worth around 2.5 billion USD, and by 2034, the figure is expected to exceed 4 billion. This growth is driven by factors such as the expansion of 5G technology, the increasing number of IoT devices, and the miniaturization and sensitivity of electronic components.

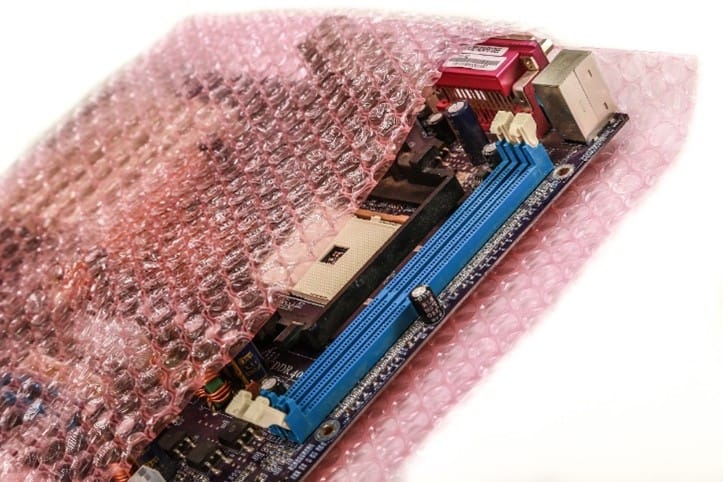

As the electronics industry evolves, packaging requirements are becoming more demanding. Amitronic Oy highlights the importance of ESD bubble wrap in protecting sensitive components. Preventing electrostatic discharge (ESD) is a critical part of safe electronics handling, and bubble wrap provides an effective solution that combines cushioning with antistatic properties.

The bubble wrap is available in 2- or 3-layer versions and made from durable LDPE plastic. The material’s thickness, bubble size (10 mm in diameter, 4 mm high), and matte surface ensure both mechanical protection and static safety. It is available in rolls suitable for various packaging needs, as well as in a range of ready-made bubble bags. The bags can be supplied with or without convenient adhesive closures. Amitronic keeps several sizes in stock, enabling fast delivery with no minimum order quantity.

In addition to pink antistatic bubble bags, Amitronic also offers long-lasting metallized bubble bags. Pink antistatic bags have a one-year lifespan and provide a practical and cost-effective way to pack, for example, printed circuit boards being shipped to end customers—after which the bag can be recycled. For long-term storage of circuit boards, such as for several years, a metallized bubble bag is the better choice, as its ESD protection remains effective for up to five years.

The use of ESD bubble wrap extends beyond the electronics industry. It is increasingly utilized in the packaging of medical devices, optical components, and automation technology—applications where static control is critical. The antistatic properties of the bubble wrap reduce the risk of damage to sensitive components during transport and storage.

Amitronic also provides consulting services in ESD protection design. Choosing the right packaging material can significantly reduce production downtime and product returns. Our experts help customers select the most suitable bubble wrap solution based on component sensitivity, transport conditions, and storage requirements.

Looking ahead, Amitronic sees the role of ESD bubble wrap continuing to grow as electronic products become smaller and more valuable. Safe packaging is no longer just an additional feature—it is an essential part of product quality and delivery reliability.

Contact our sales!